Adopting a one-piece structure can improve the structural strength of the exterior wall decorative panel, but there are also the following problems:

1 The exterior wall decorative panels are large in volume and heavy in overall quality, which is not convenient for transportation;

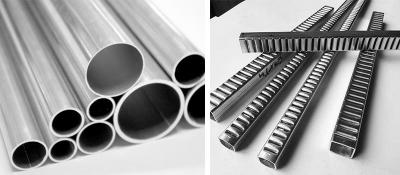

2 It is not easy to cooperate with the anchor bolt, and the installation is difficult. Difficulty in installation of alloy alloy aluminum tube rapid dryer. A rapid dryer for the production of alloy aluminum tubes: a new type discloses a rapid dryer for the production of alloy aluminum tubes, including a furnace body and a bracket arranged in the furnace body A device, an air-drying device for blowing hot air to an alloy drawn aluminium tubing, the bracket includes a bracket, a plurality of fixing frames arranged along the length of the bracket, and a lifting member used to drive one end of the bracket upward, The fixing frame is provided with a plurality of support protrusions for supporting the alloy aluminum tube, and the support protrusions are provided with positioning recesses.

The new type tilts the alloy aluminum tube. The inclined water supply flows out from one end of the alloy aluminum tube. It has a good heating effect on the alloy aluminum tube and improves the drying efficiency of the alloy aluminum tube; and by setting a fixing frame and a supporting protrusion, the It can keep no contact between the alloy aluminum tubes, so the alloy aluminum tubes are heated uniformly everywhere, and the heating effect is good. The effect of tool rust removal is not ideal. If the steel surface of the thick-walled alloy aluminum pipe is firmly attached to the surface of the iron oxide scale, the power tool can reach the Sa3 level. If the strict welding process is not adopted, the logistics transportation and other factors will vary. Can not reach the anchor depth required for anti-corrosion construction. 4 Spray rust removal: spray rust removal is driven by a high-power motor to drive the spray blades to rotate at a high speed. The price of thick-walled alloy aluminum tubes fluctuates for nearly a decade. As the temperature drops, the solubility of hydrogen decreases sharply. The seam area can also be saturated and dissolved with argon and hydrogen. Hydrogen in some defects will also make the performance embrittlement. Read more on https://www.chaluminium.com/pages/aluminium-tube.h...

3 Preparation before welding. Before welding, the groove and groove must be dried before welding when using low-hydrogen electrode. Keep the temperature at 350 degrees for 2 hours. When using, use the electrode tube to heat it at any time to reduce the content of hydrogen in the electrode. Before welding, the weld groove is preheated and the preheating temperature is 250 degrees. If the welding process occurs, the crack will be clear. Resolder. The embroidering removal of thick-walled alloy aluminum pipes after spraying and derusting are required to be welded continuously at one time for each interface is a frequently used technique in the steel pipe industry. Exterior wall decoration can improve the aesthetics of the building.